Overview

Visual Components 4.x is 3D manufacturing simulation software provided by Visual Components of Finland that facilitates the construction of virtual manufacturing equipment and high-precision operation verification and analysis. Furthermore, large size data handling (Full Vehicle data), complex shapes data handling etc are possible to operate with most efficiently. Simulation performance also maintained while using such large sized and complex data.

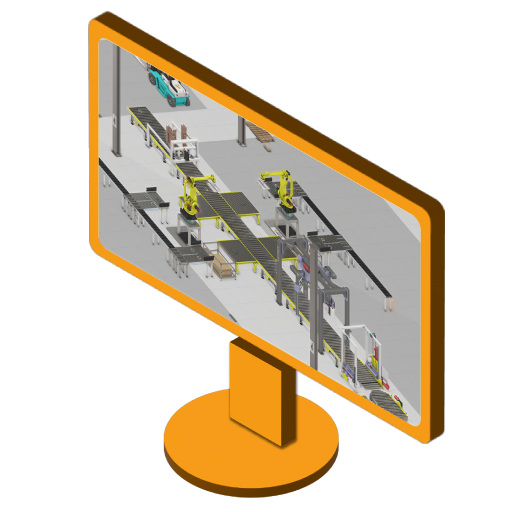

Digital Twin

A key concept of Industry 4.0, a digital twin is a dynamic, virtual, software-generated representation of physical assets and processes. With Visual Components, digital twins can be created, managed, and leveraged to support experimentation and decision-making across the production lifecycle, from initial factory design to commissioning, production planning, and process optimization – all on one platform.

Offline Programming and Virtual Commissioning

Robot offline programming and virtual commissioning are key applications of Industry 4.0, where engineers virtually validate logic programs and control changes based on a digital twin of the physical production. This yields significant cost and schedule savings for new installations, and reduced downtime when making changes to existing productions. With Visual Components, engineers have an all-in-one platform to design, optimize, and virtually commission their production systems.

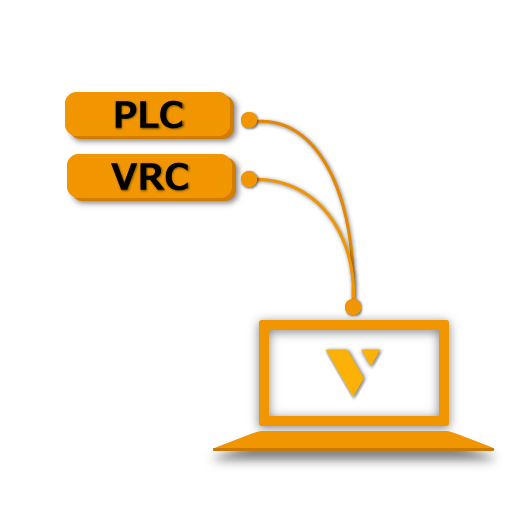

VRC/PLC Connectivity

Connectivity is key to bridging the physical and virtual worlds. It enables manufacturers to visualize their production’s real-time activity, collect and analyze data, then test and simulate improvements on a digital twin. As a vendor agnostic platform, Visual Components supports connectivity to a range of VRC and PLC systems, via the OPC UA protocol, multiple vendor specific interfaces, and the ability for users to develop their own interfaces.

Virtual Reality and Mobile

As an early developer of commercial VR and mobile solutions for manufacturing simulation, we understand the power of these platforms. Our VR solutions allow users to collaboratively design, experience, and interact with their digital factory models, whether on a single workstation or via a streaming connection with multiple participants. With our mobile apps, users can easily play, navigate, and share their Visual Components 3D animations.

Open Architecture

While there are many well defined applications of Industry 4.0, the needs of individual manufacturers will always vary, and a one-size solution won’t always fit all. That’s why we developed Visual Components with an open architecture, to encourage our users to innovate and develop custom functionalities and communication interfaces, so they can design the Industry 4.0 solutions that meet their needs.